Coagulation-Flocculation

We classify water impurities in three categories: suspended solids, colloidal particles (less than 1 micron) and dissolved substances (less than several nanometers).

The coagulation-flocculation processes facilitate the removal of suspended solids (SS) and colloidal particles.

Coagulation is the destabilization of colloidal and other suspended solid particles brought about by the addition of a chemical reagent called as coagulant.

Flocculation is the agglomeration of destabilized particles into microfloc and after into bulky floccules which can be settled called floc. The addition of another reagent called flocculant or a flocculant aid may promote the formation of the floc.

The factors, which can promote the coagulation-flocculation, are the velocity gradient, the time, and the pH. The time and the velocity gradient are important to increase the probability of the particles to come together. Moreover the pH is a prominent factor in the removal of colloids.

Our Products Includes:

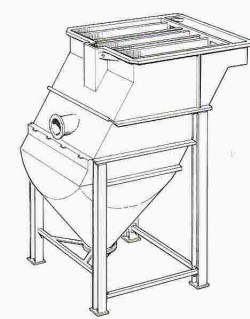

Clarifiers

Clari-floculators

Solids Contact Clarifiers

Inclined Plate Clarifiers

Tube Settlers

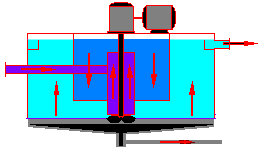

Solid Contact Clarifier:

Here settled sludge is recirculated and mixed with the incoming stream in such a way that the already settled particles form a nuclei for particle growth through flocculation created by controlled hydraulic movement of the inflow stream entering the Clarifier unit. To meet this purpose, this unit combines flash mixing, flocculation and sedimentation into a single unit for effective removal of suspended solids and other associated impurities. Chemical conditioning of inflow stream is done at flash mixing and flocculation zone of the Clarifier.

The major advantage of Solid Contact Clarifier is its smaller footprint with less than 5-ppm turbidity on most applications.

Previously formed precipitates act as unclear or to speed the reactions between the incoming raw water and treatment chemicals. Whereby making optimum use of chemicals.

Sludge particles settle at a faster rate than the rise in the clarification zone thereby achieving a clean separation between the particles the rising water.

The desired overflow clarity is achieved at high up-flow rates by optimum placement of the overflow launders as water up-flow remains vertical with minimum disturbance to solids settling.

The result is high quality clear effluent.

We sincerely take up the initiative of setting up water treatment plants. While installing, our major criteria not only lies in meeting with the time specifications, but also the highest level of engineering standards. All the required equipment are very well installed and we make sure that these are user-friendly. Adding to the user-friendliness, we ensure that minimum maintenance is required though we are always there to support at the site.

Through our set up, our major aim lies in identifying quality & quantity requirement of the client. We ensure that we never compromise in the appropriate selection of equipments and identify the required level of automation.