Water filtration for industrial water, wastewater and water recyling processes

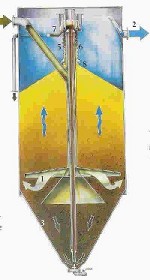

Sand Filter (SF)

Sand filtration is frequently used and very robust method to remove suspended solids from water. The filtration medium consists of a multiple layer of high silica sand with a variety in size and specific gravity. Sand filters can be supplied in different sizes and materials both hand operated or fully automatically. A special application of a sand filter is the removal of iron in surface and ground or well water. An iron removal installation consists of a aeration to oxidise and precipitate the iron and manganese, followed by removal of the precipitated particles with the sand filter. During service Water enters from the top, travels through the filtering media & goes out from the bottom. The suspended solids in the water get trapped in the filter & we get clean clear water at the outlet. This accumulated dirt (suspended solids) needs to be removed otherwise the filter will get choked & will result in less treatment flow, damage to the filter, damage to the pump, etc. The cleaning operation of the filter is called Backwash. This backwash operation needs to done once the differential pressure across the filter reaches 0.8 kg/cm2 or 24 hours of service cycle whichever is earlier. FRP Body with Multi-port valve Filtration Systems:Flow range - 1 m3/hour to 16 m3/hour. Carbon steel (Epoxy-coated) Body with C.I. valves Filtration Systems:Flow range - 7 m3/hour to 250 m3/hour. |

||||||||

|

||||||||

One valve

filter

|

||||||||

|

||||||||

Ancient civilizations knew the benefites of charred coal for improving the quality of drinking water. Today also we rely on the same principle and being used in numerous applications, is activated carbon.

FRP Body with Multi-port valve A.C. Filtration Systems:Flow range - 1 m3/hour to 16 m3/hour. Carbon steel (Epoxy-coated) Body with C.I. valves A.C. Filtration Systems: Flow range - 1 m3/hour to 350 m3/hour. |

||||||||

This accumulated dirt (suspended solids) needs to

be removed otherwise the filter will get choked & will result in less

treatment flow, damage to the filter, damage to the pump, etc. The cleaning

operation of the filter is called Backwash. This backwash operation needs

to done once the differential pressure across the filter reaches 0.8 kg/cm2

or 24 hours of service cycle whichever is earlier.

This accumulated dirt (suspended solids) needs to

be removed otherwise the filter will get choked & will result in less

treatment flow, damage to the filter, damage to the pump, etc. The cleaning

operation of the filter is called Backwash. This backwash operation needs

to done once the differential pressure across the filter reaches 0.8 kg/cm2

or 24 hours of service cycle whichever is earlier.